4.6. Motors#

A motor is a device that converts electrical energy into mechanical motion. Electric motors come in various forms but they all use electro-magnetism to create rotation. That is they use energy to create a magnetic field, which causes opposing and/or attracting forces to cause a rotation.

4.6.1. Motor Electrical Requirements#

Motors need a strong flow of current to create the magnetic fields that cause rotation. The more force (torque) a motor has to produce, the more current it draws.

Motor manufacturers will provide specifications for suitable voltage ranges and the current the motor uses under various conditions.

Danger

Important: If the motor shaft is blocked (can’t turn), the motor still tries to push current into the coils. The motor will use “stall current”, which is the maximum current the motor will ever draw. Stall current can be several times larger than the running current and may overheat or damage the motor and battery if it lasts too long.

4.6.2. Types of Motors#

Brushed DC Motors#

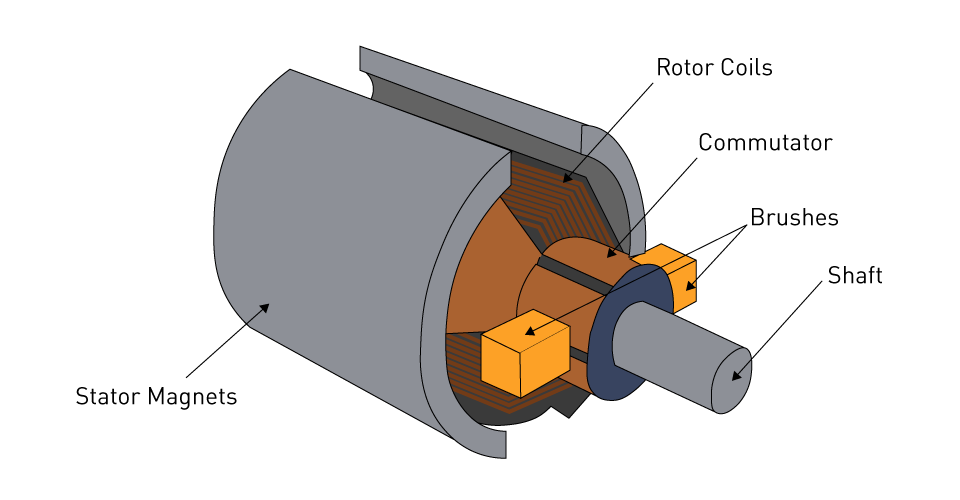

Brushed motors use “brushes” (small carbon blocks) that make slide on a commutator that is electrically connected to windings (coils) that are surrounded by stator magnets. Small breaks in the commutator disconnect the electrical connection momentary, creating alternating current and thus changing magnetic fields in the coils that repel and attract against the stator.

Brushed motors are simple to make and use. Their speed is controlled by the voltage applied to the brushes.

However the brushes are a wear item and must be replaced after long or heavy use. The brushes also add friction and lower the motor’s efficiency.

Inside a brushed DC motor.#

Brushless DC Motors (BLDC)#

Instead of brushes making contact inside the motor, with a BLDC motor electronic controllers switch the coils on and off with precise timing.

BLDC motors require relatively sophisticated controller circuitry rather than simple voltage control.

Brushless motors don’t have wear items like brushes nor the friction and efficiency losses. Moreover since energising the coils is programmable, we can dynamically control the pulses of electricity so that the motor operates with maximum efficiency.

Stepper Motors#

Stepper motors are a specialised BLDC motor where the motor is designed with a fixed number of “steps” per revolution that the motor moves through.

Stepper motors are useful when precise and predictable movement is required without feedback (open loop). They are commonly used in CNC machines and 3D printers.

Servo Motors#

Servo motors are motors equipped with a position feedback mechanism. The motors are controlled by setting an angle or rate that the motor holds or rotates at.

The type of motor used inside a servo motor varies, however in small scale robotics they are usually brushed motors.